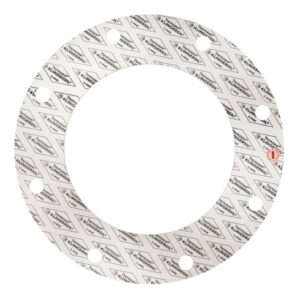

Thermoseal C4430

Outstanding stress relaxation and resistance to hot water and steam.

KLINGERSIL® C-4430 gasket offers outstanding stress retention and resistance to hot water and steam.

Basis

Optimum combination of synthetic fibre, bonded with NBR.

Areas of application

Resistant to water and steam at higher temperatures as well as to oils, gases, salt solutions, fuels, alcohols, moderate organic and inorganic acids, hydrocarbons, lubricants and refrigerants.

- Fiberglass and Aramid Fibers

- Nitrile Binder

- Excellent Steam Sheeting

- Excellent Chemical Resistance

- Good Creep Relaxation

- General purpose sheeting

Typical values refer to 1/16” material unless otherwise specified:

| Creep Relaxation ASTM F38B (1/32”) | 20% |

| Sealability ASTM F37A (1/32”) | <0.5 ml/hr |

| Gas Permeability DIN 3535/6 | <0.5 ml/min |

| Compressibility ASTM F36J | 9% |

| Recovery ASTM F36J | 50% minimum |

| Klinger Hot Compression Test | |

| Thickness Decrease 73°F (23°C) | 8% initial |

| Thickness Decrease 572°F (300°C) | 11% additional |

| Weight Increase | |

| ASTM F146 after immersion in Fuel B | |

| 5h/73°F (23°C) | 10% maximum |

| Thickness Increase | |

| ASTM F146 after immersion in | |

| ASTM Oil 1, 5h/300°F (149°C) | 0-5% |

| ASTM Oil IRM903, 5h/300°F (149°C) | 0-3% |

| ASTM Fuel A, 5h/73°F (23°C) | 0-5% |

| ASTM Fuel B, 5h/73°F (23°C) | 0-5% |

| Dielectric Strength | |

| ASTM D149-95a | 16 kV/mm |

| ASTM F104 Line Call Out | F712132B3E11K6M5 |

| Leachable Chloride Content | |

| FSA Method (Typical) | 150 ppm |

| Density ASTM F1315 | 96 lb/ft3 (1.55 g/cc) |